Production.

Quality on the track.

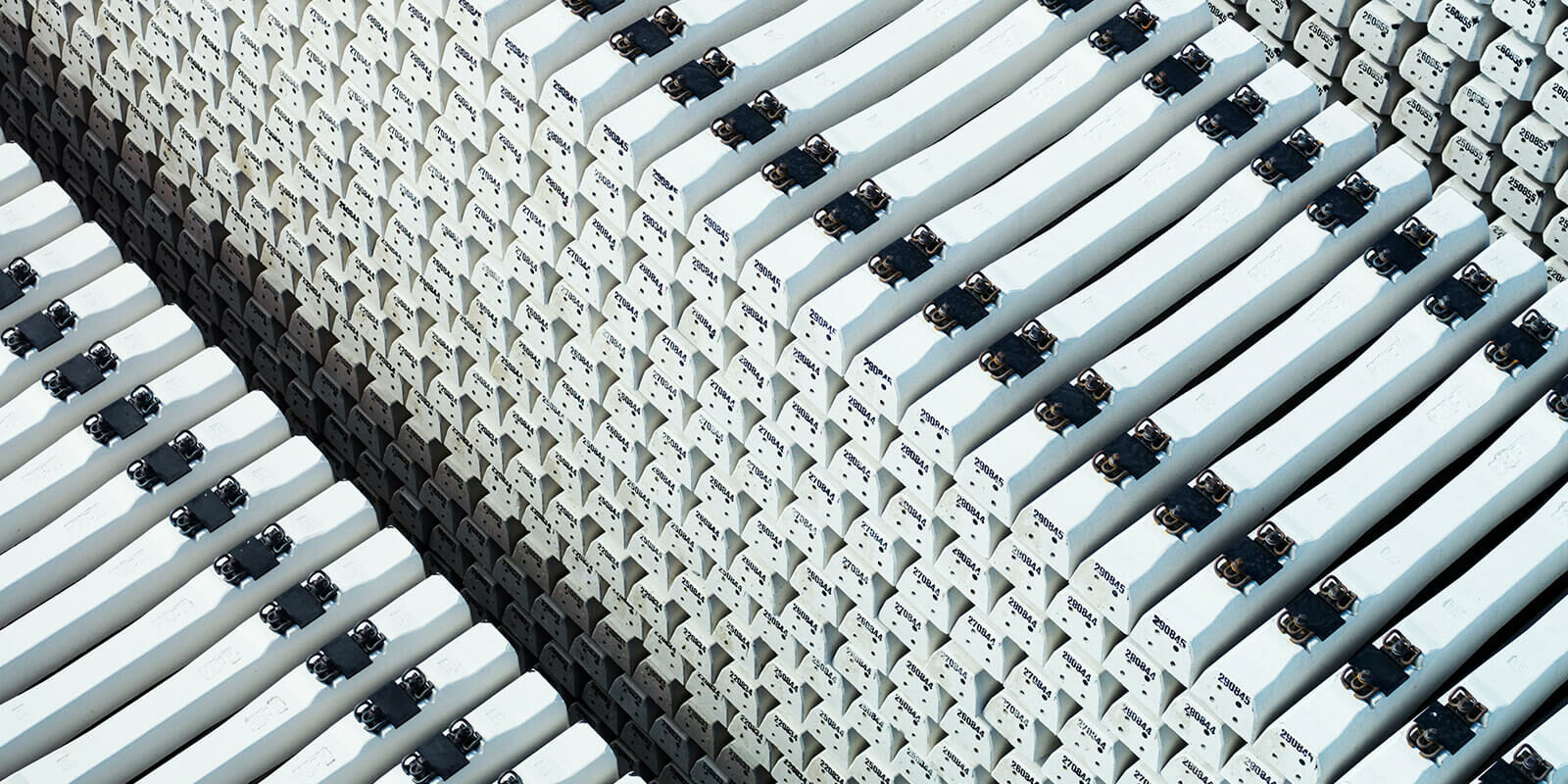

At our Möllenhagen location we operate one of the largest works for the production of prestress concrete products in Europe. With efficient production plants and large storage and loading capacity, we are able to respond flexibly and quickly to customer enquiries from home and abroad.

Our unique production control system (MES) monitors and documents the most important production processes and quality parameters. This allows us to ensure that the respective required parameters are met in all stages of the production process. The assembling and feeding of the prestressing steel is also fully-automated using plants which have been developed especially for this purpose. With our technologies we set industry standards.

Our production in Möllenhagen at a glance

Standard and special track sleepers

Latest standards, quality gates and a comprehensive production control and monitoring system ensure the consistently high quality of our products.

Turnout sleepers

The production of bearers is characterised by its high degree of individualisation. We supply the right product according to customer requirements for all standard and a large number of special purpose sleepers with individual fastening components.

Railway and catenary masts

We produce railway and overhead line masts in all required lengths up to 18 metres using a spun concrete process. The maintenance-free masts are then delivered free to the construction site by rail or self-unloading trucks.

Gravel quarrying and old sleeper recycling

Our own gravel pit on the production site provides us with optimum access to different mineral aggregates for the production of precast concrete elements and ready-mix concrete. We complete our range of supply and disposal services for railway construction sites with the recycling of waste sleepers.

Our production in Naumburg at a glance

Steel masts

We manufacture steel masts according to the highest quality standards of Deutsche Bahn (Q1), in compliance with the Deutsche Bahn regulations, rules and norms for contact line construction (Ebs) as well as the regulations for the old German National Railway (DR-M), with a maximum height of 28 meters. As a system supplier, we perform steel construction from planning to assembly.

Mast accessories

We manufacture various types of attachments, which serve as accessories, supplements, and system solutions for steel and concrete masts, as well as for tunnel electrification.

Railway steel construction

With several decades of experience in railway steel construction, we also manufacture:.

Track endings

We manufacture brake buffer stops of types 4-10, according to Deusche Bahn service regulations (DS 80001), made of used and new rail material, with track reinforcement and connecting means as well as fixed buffer stops and accessories

General steel construction

Making your vision a reality